PGFireBox 100KW

Overview

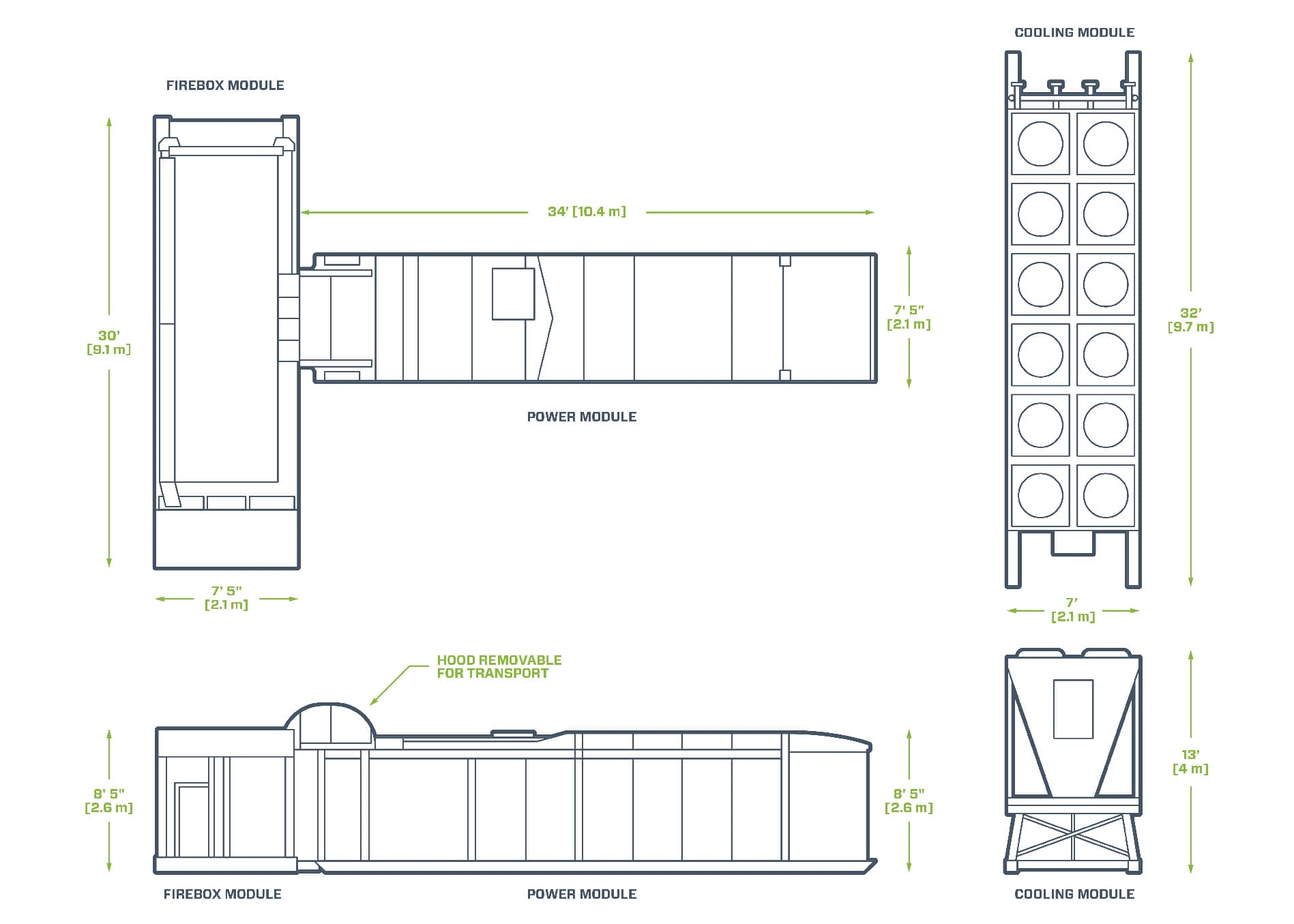

Air Burners’ PGFireBox-100 is a revolutionary new method for eliminating wood and other vegetative waste, as well as clean construction debris. At the core of the system is Air Burners’ patented FireBox technology which has been tested and approved by regulatory agencies around the globe. The PGFireBox can eliminate up to eight tons per hour [7.2 mt/h] of waste material while simultaneously producing up to 100 kW of clean, emission-free energy without the use of supplemental fossil fuels.

In addition, the PGFireBox does not require any of the costly and emissions-intensive pre-processing (grinding/chipping/sorting) of fuel required by conventional biomass power generating systems. The PGFireBox consumes whole logs, limited only by the length of the FireBox in the system (generally 20 ft [6 m]). The volume of the waste material is reduced by approximately 98%, leaving only a small quantity of ash and biochar that can be repurposed for agricultural or other uses.

A portion of the ‘waste’ heat in the exhaust from the PGFireBox is captured and directed to a heat exchanger to produce hot water (300°F [150°C] or less), which in turn supplies an Organic Rankine Cycle (ORC) power generating unit. The ORC utilizes a non-ozone-depleting organic working…

Air Burners’ PGFireBox-100 is a revolutionary new method for eliminating wood and other vegetative waste, as well as clean construction debris. At the core of the system is Air Burners’ patented FireBox technology which has been tested and approved by regulatory agencies around the globe. The PGFireBox can eliminate up to eight tons per hour [7.2 mt/h] of waste material while simultaneously producing up to 100 kW of clean, emission-free energy without the use of supplemental fossil fuels.

In addition, the PGFireBox does not require any of the costly and emissions-intensive pre-processing (grinding/chipping/sorting) of fuel required by conventional biomass power generating systems. The PGFireBox consumes whole logs, limited only by the length of the FireBox in the system (generally 20 ft [6 m]). The volume of the waste material is reduced by approximately 98%, leaving only a small quantity of ash and biochar that can be repurposed for agricultural or other uses.

A portion of the ‘waste’ heat in the exhaust from the PGFireBox is captured and directed to a heat exchanger to produce hot water (300°F [150°C] or less), which in turn supplies an Organic Rankine Cycle (ORC) power generating unit. The ORC utilizes a non-ozone-depleting organic working fluid in a 'reverse refrigeration process' where the thermal energy input to the system is converted to electrical energy by driving an asynchronous (induction) generator. The system is typically connected to the local electrical grid in a ‘Net Metering’ arrangement like rooftop solar (depending on local regulations) where either some or all of the energy is consumed on site and any excess energy produced is sold back to the utility.

Aside from the electrical grid connection, only a cooling source is required at the site. This can be a portable air blast cooler supplied by Air Burners or local water cooling. Local water cooling can include a river or lake. The cooling water is completely isolated from the PGFireBox working fluids and none of the water is consumed. The local cooling water returns to the source unchanged except for a small temperature rise.