Air Burners Recycles Wood Waste—Smarter, Cleaner, and Right Where You Need It

Wood waste is piling up across the country—on job sites, in forests, after storms, and during land clearing. We generate over 70 million tons of it every year in the U.S. alone. And while “recycling” sounds like the responsible choice, traditional wood recycling isn’t always the win it’s made out to be.

Between all the hauling, grinding, sorting, and processing, the system burns through fuel, time, and money—only to dump most of that wood right back into landfills or biomass burners.

At Air Burners, we do it differently.

We eliminate wood waste on-site—cleanly, quickly, and with less environmental impact. And we call that recycling. Because what we’re really doing is recovering value from wood that would otherwise be wasted—turning it into heat, power, and even carbon-sequestering biochar.

The Problem with “Traditional” Wood Recycling

It’s Expensive and Inefficient

Let’s be honest: traditional recycling often costs more than it’s worth.

You need trucks, fuel, permits, and labor just to haul the material.

You spend more to grind and screen it.

And in the end, most of it still gets tossed or burned elsewhere.

All that effort—for a tiny return.

Strong Market for Recycled Wood

Unlike metal or plastic, recycled wood has limited demand. Most of it is too dirty, damaged, or inconsistent to repurpose. Even when it is reused, the market is weak—and the value is low.

The Carbon Footprint Can Be Worse

From the first truckload, emissions start climbing:

Diesel engines for hauling

Diesel machines for processing

Methane release from landfill disposal

Ironically, the process meant to reduce waste and emissions often creates more of both.

Air Burners: A Better Way to Recycle Wood Waste

Our approach is simple: keep the wood where it is, eliminate it on-site, and recover as much value from it as possible.

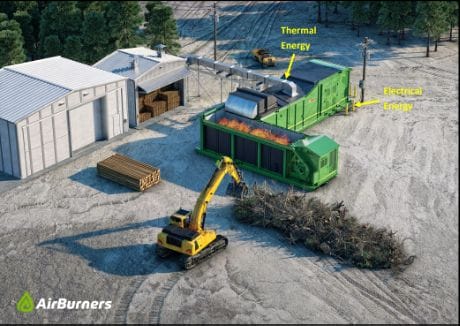

With our patented air curtain burners—like the CharBoss, BurnBoss, and BioCharger—you can:

Eliminate waste without grinding or hauling

Dramatically cut smoke and emissions

Create clean electricity (with the BioCharger)

Produce biochar that improves soil and locks away carbon

This isn’t theoretical—it’s field-proven.

What We Mean by “Recycling”

We may not be shredding pallets into mulch, but we are recycling. Here’s how:

On-site waste removal = no long-distance hauling

Biochar production = carbon capture and soil improvement

Waste-to-energy (via BioCharger) = clean, localized power

Cleaner air = fewer particulates, no uncontrolled burns

In short, we’re turning waste into something useful—without the middle steps that waste time, money, and fuel.

Who’s Using Air Burners?

If you manage land or operations that produce wood debris, this is for you.

Forestry & Land Clearing: Eliminate slash piles, reduce fire risk, improve forest health

Construction & Demolition: Handle wood debris on-site without costly removal

Agriculture: Convert trimmings into biochar for more resilient fields

Disaster Recovery: Get up and running fast after hurricanes, floods, or fires

Cities & Counties: Reduce landfill pressure and improve local air quality

Why Biochar Is a Game Changer

Biochar is a stable, carbon-rich material left over after high-efficiency burning. It’s packed with benefits:

Sequesters carbon in soil for centuries

Boosts soil health and water retention

Helps reduce fertilizer use

Qualifies for many climate-smart land management programs

It’s one of the few tools that helps you reduce emissions while improving land performance.

Bottom Line: Wood Waste Recycling Needs to Catch Up

The old model of grinding, trucking, and hoping for resale value isn’t cutting it anymore.

Air Burners gives you a cleaner, faster, smarter alternative.

We bring the solution to you—no hauling, no processing centers, no wasted effort. Just practical, scalable tech that turns waste into real environmental value.

Let’s stop managing wood waste like it’s 1995.

See what Air Burners can do for your land, your crew, and your bottom line.

Visit airburners.com to learn more or talk with our team.