Air Curtain Burners vs. Biomass Facilities

What’s the Real Cost of Wood Waste? Take a Look.

This image tells a story—one most wildfire mitigation planners and forest managers know all too well.

To get wood waste here, forests were cleared, trees were ground with diesel-powered machines, loaded into trucks, and hauled to this centralized chip pile. All of it under the banner of “sustainable disposal.”

But grinding and hauling isn’t sustainable—it’s a logistical, environmental, and financial drain.

It’s time to reevaluate the real cost of traditional biomass disposal and understand why air curtain burners are rapidly gaining recognition as the cleaner, faster, and more effective approach to wildfire mitigation and forest protection.

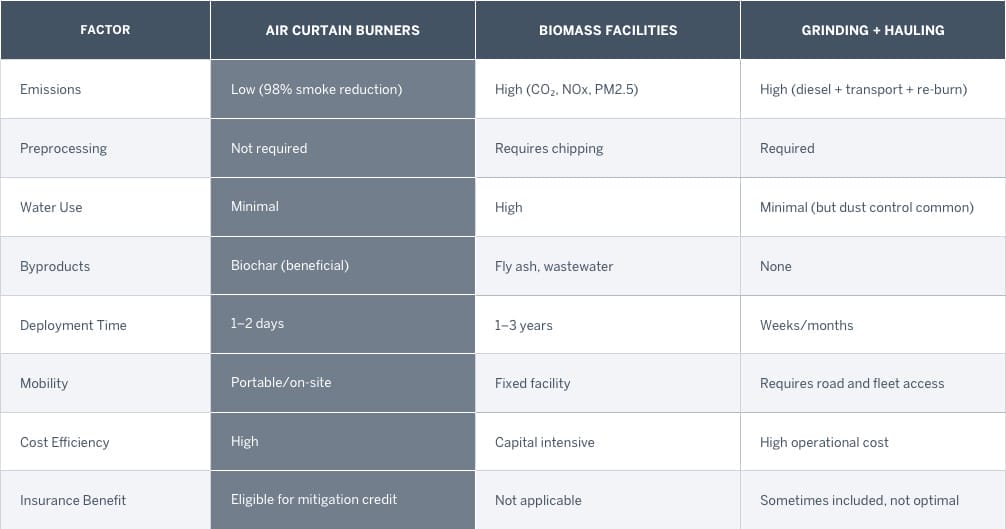

Biomass Facilities: Centralized Energy With a Hidden Footprint

Biomass power plants burn organic waste—primarily chipped or pelletized wood—to generate heat or electricity. While technically “renewable,” the entire operation is resource-heavy:

- Requires wood preprocessing (grinding, drying, handling)

- Involves hauling large volumes of material to centralized facilities

- Releases CO₂, methane, NOx, and PM2.5, even with scrubbers

- Consumes high volumes of water for cooling and filtration

- Produces fly ash and wastewater requiring specialized disposal

- Demands millions in capital and 1–3 years to build

In short: biomass plants are built for utility-scale power—not fast, flexible wildfire mitigation.

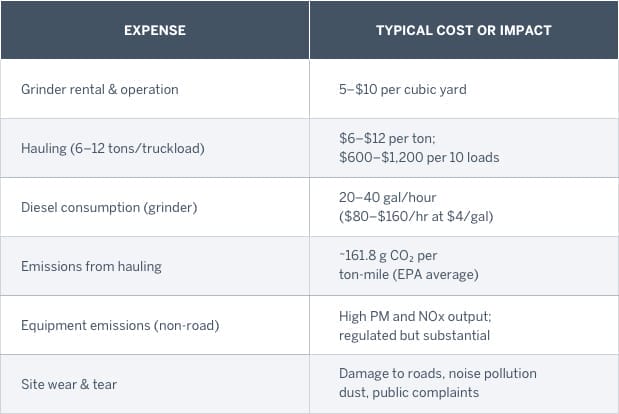

Grinding and Hauling: The Numbers Tell the Story

Let’s break down the often-overlooked costs of preprocessing and transporting wood waste:

This model relies on constant fuel, complex scheduling, and high emissions—all to move waste from Point A to Point B, only to burn it at Point C.

Air Curtain Burners: Burn On-Site. Burn Clean. Burn Smarter.

Air Curtain Burners—also known as FireBoxes—were originally developed as air pollution control devices for open burning. Their primary purpose is to reduce particulate matter (PM)—the visible smoke that results from burning clean wood waste—by using a high-efficiency combustion method called the air curtain.

In operation, clean wood waste is loaded into a firebox and ignited, similar to starting a controlled burn pile. Once the fire reaches sufficient strength, the air curtain system is engaged.

The Air Curtain acts like an invisible lid over the firebox. A high-velocity stream of air is directed across the top of the combustion chamber, trapping rising smoke particles and forcing them back down into the flame, where they are reburned and broken down into smaller, less visible particles.

This creates a secondary burn chamber effect, dramatically reducing smoke opacity.

The result? A much cleaner, more complete burn that complies with U.S. EPA clean air standards—without the need for chipping, hauling, or centralized infrastructure.

Air Burners’ machines process waste at burn rates ranging from 1 ton per hour (Boss Series) to 13 tons per hour (S330-Series) – with many options to fit your fleet—making them ideal for wildfire mitigation, forest restoration, and emergency debris response.

Key Features:

- No preprocessing (logs, brush, and root balls go in as-is)

- Operates directly on-site—eliminating hauling emissions

- Requires minimal water, significantly less than biomass plants

- Produces ash and biochar—enhancing soil and sequestering carbon

- Deployed in 1–2 days, anywhere from remote forests to urban zones

- Tested by the U.S. Forest Service, EPA, and Department of Energy

Why This Matters for Wildfire Mitigation

Air curtain burners should be a core component of wildfire mitigation and community risk reduction strategies. Here’s why:

Eligible for Insurance Discounts

Fire Safe Councils and municipalities can often qualify for wildfire insurance credits by showing proactive fuel load reduction using approved methods. Air Burners’ systems help meet these benchmarks.

No Grinding = Faster Mitigation

Skip the long wait for grinder availability and truck scheduling. Air curtain burners deploy in days and start burning immediately.

Clean Operation = Community Support

With <10% visible opacity and no heavy truck traffic, you can keep neighborhoods and stakeholders on your side—no smoke complaints, road damage, or illegal dumping concerns.

Ash and Biochar = Long-Term Climate Resilience

Turn waste into a carbon-sequestering soil amendment that improves drought resistance, nutrient retention, and ecosystem restoration.

Real-World Applications

- U.S. Forest Service: Uses Air Burners to reduce wildfire risk by eliminating excess timber directly in the field.

- State & Local Fire Councils: Replace open burning with cleaner combustion that’s compliant and cost-effective.

- Storm Recovery Teams: Rapid debris cleanup after hurricanes, tornadoes, or wind events—no grid required.

- Construction & Agriculture: Manage green waste while producing biochar for local reuse or carbon credits.

Air curtain burners aren’t just an alternative to biomass—they’re a full-system rethink for sustainable wood waste disposal.

Instead of hauling chips across counties to sit in piles, you can eliminate fuel loads at the source, protect forests, reduce emissions, and even improve soil—all while saving money.

If you’re managing wildfire risk, disaster recovery, or forest thinning programs, skip the chip pile. Burn smarter.

Ready to Protect Forests Without the Chips and Emissions?

We’ll help you plan a clean, fast, cost-effective mitigation strategy—no grinders required.