Air Curtain Burner Technology

Problem

Woody biomass and vegetative waste is a worldwide problem. According to agencies like the USEPA and the World Bank, this type of waste accounts for about 20 to 30 percent of all waste. In 2014,(USEPA) reported the USA collected approximately 70 million tons of “urban” biomass waste, and only 30 percent of that waste was recycled. The balance went in our landfills. In addition to this “urban” biomass waste, we also have forests and national parks filled with dead and dying trees due to climate change, drought, infestation, etc. In California alone, the U.S. Forest Service (2016) counted 102 million standing dead trees. This is approximately 800 million tons of biomass waste that needs to be eliminated. This "tree mortality" is even more important because not only is this a danger to people and property but this represents the loss of a significant carbon sink; disrupting the balance of CO2 and oxygen on our planet. Nobody knows for sure how big the tree mortality problem is, but; 1) it is worldwide, and 2) it is exponentially greater than 800 million tons, and 3) these dead trees need to be replaced so the green cycle of CO2 "in" and oxygen "out" can continue.

Recycle

Why aren't we recycling all this biomass waste? We are trying, but 30 percent is all the market will absorb at this time. Our typical recycling methods are 1) energy, 2) mulch, and 3) pellets. Unfortunately, all three of these options require more energy to produce in grinding, sorting, and chipping than they contribute in recycled savings, with the net result being negative, both economically and environmentally. The reason most of today’s biomass energy systems never gain a strong foothold is the cost. Preprocessing all the biomass drives the energy costs too high to compete with standard power generation. Even solar and wind power have been able to get their costs in the competitive range. For today's biomass energy systems, the material needs to be sorted, then ground up and finally chipped to a very particular size. All of these processes use diesel fuel. When you add in all the trucking, it's almost impossible to make it work without government subsidies. That's not the case with the PGFireBox.

As a world community, we need to focus first on elimination and second on advanced recycling, developing better recycling methods that capture energy and produce a marketable product.

Eliminating the waste.

For over 20 years, Air Burners has been manufacturing Air Curtain Burners, the most cost effective and environmentally friendly method of eliminating wood and vegetative waste. We are committed to protecting our environment. To prove that, we are the only manufacturer that participated in testing programs with some of the world's most prestigious environmental agencies, including the United States EPA, the UK Environmental Agency, the Canadian Department of the Environment, and the Australian Environmental Agency. We have the most proven product line on the planet, but we are always striving to be better.

Advanced recycling.

We are just introducing our PGFireBox series now. These machines will revolutionize biomass energy generation, with the lowest costs and the lowest environmental impact on the market. The PGFireBox is the next step in advancing our options for recycling and achieving better usage of this waste stream.

Solution

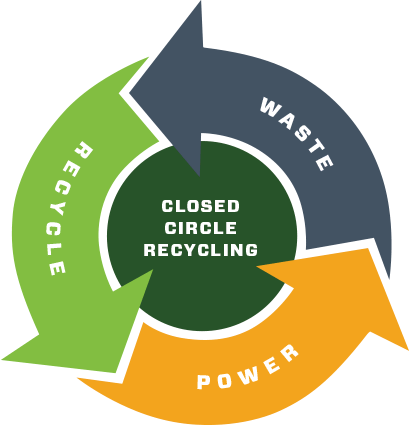

At Air Burners, we are working toward a new methodology in recycling wood and vegetative waste that combines elimination with producing a marketable product. We call this methodology Closed Circle Recycling. The basic concept is to establish a biomass energy generation facility that does not require preprocessing, paired with a system that can be relocated. That system is the PGFireBox. With the PGFireBox, we can eliminate this waste stream while generating electricity. This electricity is then used at the site to run machines producing biomass products like biochar, wood pellets, mulch and others. This system lowers the overall cost of manufacturing these products, thereby giving them a much better chance at success in the market. The PGFireBox will be the center of tomorrow’s wood and vegetative waste recycling facility.

Closed Circle Recycling: The Next Tool for the Biomass Industry

The graphic above depicts a Closed Circle Recycling facility. At the center is the Air Burners 100kW, a 100kW power generating machine. Surrounding the 100kW are various electrically powered wood processing machines. One of the main advantages of a facility like this is that it is not permanent. If the wood waste stream should diminish, the entire facility can be moved or sold to another location. The 100kW will eliminate between 8 and 20 tons of wood waste per hour, which will either generate revenue from tipping fees, or will save the cost of disposing of the waste stream. Either way, the income starts with the PGFireBox. From there, additional electric powered machines are added to manufacture recycled products that can be marketed, generating more income.

The PGFireBox can accept all types of vegetative waste, including decayed or diseased trees, and root balls. No other system has operating costs as low as the PGFireBox. because none of the waste material needs to be preprocessed, it is delivered to the site and goes straight in the FireBox, no grinding no chipping. Additionally it burns naturally so no secondary fuel source is needed, it's the same as open burning except the emissions are controlled by the air curtain technology.