Air Curtain Burner Technology

Inside Air Burners' Patented Air Curtain Burner Technology

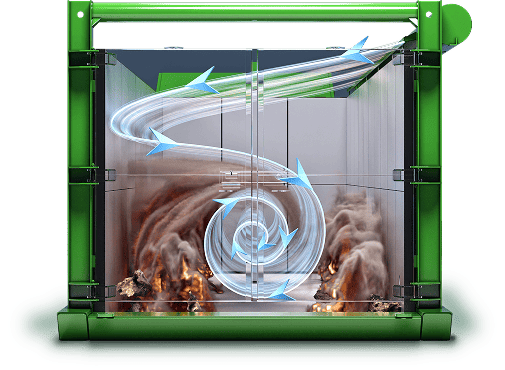

At the core of every Air Burners FireBox is a proprietary air curtain system engineered to burn wood waste efficiently and cleanly. The technology uses a high-velocity “air curtain” to control airflow and trap smoke particles, resulting in near-complete combustion with minimal emissions.

How It Works

- Waste is loaded into a refractory FireBox chamber.

- A powerful blower system creates a high-speed air curtain over the burn chamber.

- The air curtain traps particulates, extends combustion, and ensures clean burning.

- Ash and biochar remain, leaving zero unburned debris.

Operation

The image shows two Air Burners FireBox S-327 series machines completely full and burning, while in the background, a pile of wood is open burned. The same amount of wood, 20 tons, was used at each of the two sites. The FireBoxes eliminated the 20 tons of waste wood in one hour. The open pile burned for more than 48 hours to handle the same amount of waste wood.

The picture to the right is an aerial view of this site. It shows the environmental impact of open burning versus air curtain burning. To eliminate 20 tons of wood waste, the FireBoxes took one hour, while the open burn took in excess of 48 hours. The open pile burn filled the valley with black carbon smoke, while the Air Burners were almost undetectable.

Burning onsite eliminates the need for grinders and trucks. Plus, it is much faster, saving money and protecting the environment.

How It Works

The most concerning black carbon smoke particles are the ones you can’t see. They are called PM2.5, and consist of particulate matter that is under 2.5 microns in size. These are the particulates that can hurt you, as they are small enough to get past your body's defenses. No other machine used for wood waste elimination, including grinders and chippers, can control PM2.5 as well as an Air Burners machine. Our air curtain works.

For proper operation, the air curtain machine has to be designed to provide a curtain of air over a fire that has a mass flow and velocity in balance with the potential mass flow and velocity of the burning wood waste. If the air curtain velocity is too high, the FireBox can become over pressurized and over agitated. The higher pressure will lift the curtain and cause it to become ineffective. The over-agitation will cause embers and ash to be blown out of the FireBox past the ineffective air curtain at a significantly higher rate than normal. If the mass flow of the curtain is too low. the unburned particles (smoke) will penetrate the curtain on the high velocity of the hot gases being generated from the burning wood. Air Burners machines have been thoroughly tested by some of the finest environmental agencies in the world, including the U.S. EPA, EA UK, EPA Australia, and more to prove our ability to control particulate release and to control PM2.5 release.

FAQ

What is the difference between a FireBox and a grinder for wood waste removal?

A grinder mechanically shreds wood waste into chips using high horsepower engines that consume large amounts of diesel fuel—about 30 gallons per hour. In contrast, an Air Burners FireBox (like the S330) uses an air curtain to eliminate waste through controlled combustion, consuming only 2.5 gallons per hour.

While a grinder leaves 98 tons of material that must still be hauled to a landfill, a FireBox reduces 100 tons of waste to about 3 tons of BioChar and ash, which can be reused as soil amendment.

How much does it cost to remove 100 tons of wood waste using a FireBox versus grinding?

Fuel consumption and disposal costs make grinding significantly more expensive.

- Grinder: 1050 HP engine burns ~30 gal/hour × $4.00/gal = $120/hour; requires 1 hour for 100 tons.

- FireBox S330: 2.5 gal/hour × $4.00/gal = $10/hour; requires 8 hours for 100 tons.

When factoring in landfill transport, grinder maintenance, and particulate pollution controls, Air Burners FireBoxes can reduce total disposal cost by 60–70% compared to grinding.

Is burning with an Air Curtain Burner environmentally friendly?

Yes. Air Curtain Burners are designed for pollution control. The air curtain traps smoke and particulate matter, causing it to re-burn at high temperatures. The resulting emissions are mostly non-carcinogenic carbon, unlike the fine wood dust produced by grinding—which is a known carcinogen.

In fact, Air Burners systems have been tested and verified by the U.S. EPA, the UK Environmental Agency, and other international bodies for compliance and emissions performance.

What is “Closed Circle Recycling” and how does it work?

Closed Circle Recycling is Air Burners’ next-generation approach to biomass waste management. It combines elimination and advanced recycling using the PGFireBox® system.

The process eliminates wood and vegetative waste on-site while generating electricity to power machines that create marketable recycled products like BioChar, wood pellets, and mulch—all without consuming fossil fuels or requiring material preprocessing.

Why is the PGFireBox more efficient than traditional biomass power plants?

Traditional biomass power plants require preprocessing steps—sorting, grinding, and chipping—that consume diesel fuel and make operations costly.

The PGFireBox accepts unprocessed material, including root balls, diseased trees, and mixed vegetative waste, and burns naturally without secondary fuel.

This eliminates costly preprocessing, reduces transport emissions, and generates renewable energy directly from the waste stream.

How much energy can the PGFireBox generate?

The PGFireBox 100kW can eliminate 8–20 tons of wood waste per hour while generating up to 100 kilowatts of electricity.

That energy can be used to power nearby recycling machines, run local facilities, or feed into small grid systems. It’s ideal for remote forestry operations, disaster recovery sites, and portable recycling centers.

Can Air Burners systems help reduce wildfire risk?

Yes. Air Burners technology helps mitigate wildfire hazards by safely eliminating dead and diseased trees, forest debris, and invasive vegetation

that fuel wildfires.

Unlike open burning or grinding, the FireBox burns cleanly and on-site, reducing both transportation emissions and wildfire ignition sources

What happens to the ash and BioChar produced by the FireBox?

After burning, the FireBox leaves behind approximately 3 tons of BioChar and ash per 100 tons of waste.

This byproduct can be mixed into soil for improved fertility or sold as a soil amendment, making the process both environmentally and economically sustainable.

Is the Air Burners FireBox portable?

Yes. Every Air Burners FireBox and PGFireBox model is fully portable and can be moved or sold to another site as needed.

This mobility makes them ideal for forestry, land clearing, disaster response, and municipal waste operations where flexibility is critical.

How does the Air Curtain Burner support sustainability goals?

Air Burners systems reduce landfill waste, eliminate harmful grinding emissions, and convert waste into renewable energy and soil products.

They support carbon reduction, landfill diversion, and circular economy goals for municipalities and private operators worldwide.